Wycinarka Laserowa Eagle eVision 4kW

Szybkość. Dokładność. Technologia przyszłości.

Wycinarka laserowa Eagle eVision 4kW to zaawansowane technologicznie urządzenie do cięcia blach, które zapewnia wyjątkową precyzję oraz imponującą wydajność. Dzięki źródłu lasera o mocy 4 kW i lekkiej osi napędzanej silnikami liniowymi, maszyna umożliwia cięcie z dużą prędkością przy zachowaniu najwyższej jakości krawędzi.

Najważniejsze cechy:

- Moc lasera: 4 kW (fiber)

- Obszar roboczy: 3000 x 1500 mm

- Szybkość pozycjonowania: nawet 150 m/min

- Dokładność cięcia nawet w przypadku cienkich i trudnych materiałów

- Automatyczny stół załadowczo-rozładowczy dla zwiększenia efektywności pracy

- Doskonała jakość krawędzi bez potrzeby dodatkowej obróbki

Eagle eVision to rozwiązanie dla tych, którzy oczekują szybkości, niezawodności i najwyższej jakości cięcia – zarówno przy produkcji prototypów, jak i dużych serii.

Prasa Krawędziowa Trumpf TruBend 3100

Prasa krawędziowa Trumpf TruBend 3100 to nowoczesne rozwiązanie do gięcia blach, które łączy niemiecką precyzję z intuicyjną obsługą i wysoką wydajnością. Idealna do produkcji jednostkowej oraz seryjnej, umożliwia uzyskanie powtarzalnych wyników nawet przy najbardziej wymagających gięciach.

Najważniejsze cechy:

- Siła nacisku: 100 ton

- Długość gięcia: 3000 mm

- Wysoka dokładność pozycjonowania i kąta gięcia dzięki systemowi pomiaru kąta

- Intuicyjny interfejs sterowania Touchpoint TruBend

- Możliwość gięcia złożonych kształtów i cienkościennych detali

- Stabilna i sztywna konstrukcja zapewniająca długą żywotność

Dzięki prasie TruBend 3100 oferujemy naszym klientom kompleksową usługę gięcia blach z najwyższą precyzją, niezależnie od kształtu i wielkości detalu.

CNC Okuma Genos M660

Zastosowanie w różnych branżach, takich jak przemysł lotniczy, motoryzacyjny, elektroniczny i medyczny. Jest wykorzystywana do produkcji precyzyjnych elementów, prototypów, form wtryskowych i wyrobów gotowych

Kluczowe cechy:

- Rozmiar stołu: 660x 1530 mm.

- Prędkość wrzeciona: 15,000 obr./min.

- Moc silnika wrzeciona: 22 kW.

- Pojemność magazynu narzędzi: 32 sztuki.

Nośność stołu : 1500 kg

- Aluminium

- Stal nierdzewna

- Stal węglowa

- Mosiądz

- Miedź

- Tytan

- Inconel

- Oraz wiele innych materiałów

Urządzenie to cechuje się elastycznością dzięki magazynowi narzędzi na 32 sztuki oraz doskonałą wydajnością cięcia dzięki wrzecionu 15K CAT40 BIG-PLUS®. Wyróżnia się również wysoką sztywnością dzięki konstrukcji z podwójną kolumną.

GENOS 560-V-E oferuje wyjątkową stabilność termiczną, co pozwala na obróbkę różnorodnych materiałów, od tytanu po aluminium, bez naruszania jakości wykończenia.

Okuma Genos 560-V-E

Zastosowanie w różnych branżach, takich jak przemysł lotniczy, motoryzacyjny, elektroniczny i medyczny. Jest wykorzystywana do produkcji precyzyjnych elementów, prototypów, form wtryskowych i wyrobów gotowych

Kluczowe cechy:

- Rozmiar stołu: 560 x 1300 mm.

- Prędkość wrzeciona: 15,000 obr./min.

- Moc silnika wrzeciona: 22 kW.

- Pojemność magazynu narzędzi: 32 sztuki.

Nośność stołu : 900 kg

- Aluminium

- Stal nierdzewna

- Stal węglowa

- Mosiądz

- Miedź

- Tytan

- Inconel

- Oraz wiele innych materiałów

Urządzenie to cechuje się elastycznością dzięki magazynowi narzędzi na 32 sztuki oraz doskonałą wydajnością cięcia dzięki wrzecionu 15K CAT40 BIG-PLUS®. Wyróżnia się również wysoką sztywnością dzięki konstrukcji z podwójną kolumną.

GENOS 560-V-E oferuje wyjątkową stabilność termiczną, co pozwala na obróbkę różnorodnych materiałów, od tytanu po aluminium, bez naruszania jakości wykończenia.

Okuma LB 3000 EXII MY

Tokarki CNC z osią Y, umożliwiające frezowanie, oferują rozszerzone możliwości obróbki skrawaniem w porównaniu do tradycyjnych tokarek. Dzięki osi Y, która dodaje ruch pionowy do standardowych ruchów osi X (ruch poziomy) i Z (ruch wzdłużny), tokarki CNC z osią Y są w stanie wykonywać precyzyjne operacje frezowania, co umożliwia tworzenie skomplikowanych kształtów i detali.

Kluczowe cechy:

- Przelot nad łożem: 520 mm

- Maksymalna średnica toczenia 340 mm

- Maksymalna długość toczenia 950 mm

- Maksymalna obciążenie wrzeciona 650 kg

- Moc silnika wrzeciona: 22 kW

- Prędkość obrotowa wrzeciona: 38 ~ 3800 obr./min

Narzędzia obrotowe:

- Zakres obrotów narzędzi: 45 ~ 6000 obr./min

- Maksymalna moc silnika napędzanych narzędzi: 5,5 kW

- Siła docisku: 6,5 kN

- Aluminium

- Stal nierdzewna

- Stal węglowa

- Mosiądz

- Miedź

- Tytan

- Inconel

- Oraz wiele innych materiałów

Okuma Genos L3000-e

Tokarki CNC z osią Y, umożliwiające frezowanie, oferują rozszerzone możliwości obróbki skrawaniem w porównaniu do tradycyjnych tokarek. Dzięki osi Y, która dodaje ruch pionowy do standardowych ruchów osi X (ruch poziomy) i Z (ruch wzdłużny), tokarki CNC z osią Y są w stanie wykonywać precyzyjne operacje frezowania, co umożliwia tworzenie skomplikowanych kształtów i detali.

Kluczowe cechy:

- Przelot nad łożem: 520 mm

- Maksymalna średnica toczenia 390 mm

- Maksymalna długość toczenia 950 mm

- Maksymalna obciążenie wrzeciona 650 kg

- Moc silnika wrzeciona: 22 kW

- Prędkość obrotowa wrzeciona: 38 ~ 3800 obr./min

Narzędzia obrotowe:

- Zakres obrotów narzędzi: 45 ~ 6000 obr./min

- Maksymalna moc silnika napędzanych narzędzi: 5,5 kW

- Siła docisku: 6,5 kN

- Aluminium

- Stal nierdzewna

- Stal węglowa

- Mosiądz

- Miedź

- Tytan

- Inconel

- Oraz wiele innych materiałów

Tokarka CNC Okuma GENOS L3000-e to zaawansowane urządzenie wykorzystujące wbudowane wrzeciono do dokładnej obróbki CNC. Ta tokarka, będąca mocniejszą, doskonale radzi sobie z obróbką wielu nietypowych materiałów. Wbudowany napęd wrzecionowy zwiększa możliwości obróbkowe, podczas gdy solidne prowadnice umożliwiają intensywne cięcie. Ta wysoko zaawansowana tokarka oferuje różnorodne funkcje, takie jak wysokoprędkościowe frezowanie i korzystanie z osi Y .Wykorzystanie technologii stabilizatora termoaktywnego TAS-C, pozwala na automatyczne rekompensowanie wpływu temperatury i utrzymanie ścisłych tolerancji.

Okuma Genos 560-V-E

Zastosowanie w różnych branżach, takich jak przemysł lotniczy, motoryzacyjny, elektroniczny i medyczny. Jest wykorzystywana do produkcji precyzyjnych elementów, prototypów, form wtryskowych i wyrobów gotowych

Kluczowe cechy:

- Rozmiar stołu: 560 x 1300 mm.

- Prędkość wrzeciona: 15,000 obr./min.

- Moc silnika wrzeciona: 22 kW.

- Pojemność magazynu narzędzi: 32 sztuki.

Nośność stołu : 900 kg

- Aluminium

- Stal nierdzewna

- Stal węglowa

- Mosiądz

- Miedź

- Tytan

- Inconel

- Oraz wiele innych materiałów

Urządzenie to cechuje się elastycznością dzięki magazynowi narzędzi na 32 sztuki oraz doskonałą wydajnością cięcia dzięki wrzecionu 15K CAT40 BIG-PLUS®. Wyróżnia się również wysoką sztywnością dzięki konstrukcji z podwójną kolumną.

GENOS 560-V-E oferuje wyjątkową stabilność termiczną, co pozwala na obróbkę różnorodnych materiałów, od tytanu po aluminium, bez naruszania jakości wykończenia.

5 Osiowe Studio CNC Seron

Maszyny CNC 5-osiowe to zaawansowane narzędzia do obróbki skrawaniem, które umożliwiają ruch narzędzia w pięciu niezależnych osiach. Oprócz standardowych ruchów osi X, Y i Z, maszyny CNC 5-osiowe są w stanie wykonywać ruchy obrotowe wokół osi A i B, co zapewnia większą swobodę i precyzję podczas obróbki skrawaniem.

Dzięki pięciu osiom ruchu, maszyny CNC 5-osiowe umożliwiają skrawanie z różnych kątów i pozycji, co jest szczególnie przydatne przy obróbce trudno dostępnych obszarów i wykonywaniu skomplikowanych kształtów. Maszyny te pozwalają na wykonanie operacji frezowania, wiercenia, gwintowania i innych operacji obróbczych z wysoką precyzją i efektywnością

Kluczowe cechy:

Maksymalne wymiary obróbki: 2000 x 3000 x 1000 mm.

- Rozmiar stołu: 2100 x 3100mm

- Zakres w osi Z: 1000 mm

- Prędkość wrzeciona: 24,000 obr./min

- Moc silnika wrzeciona: 13,5 kW

- Pojemność magazynu narzędzi: 34 sztuki

- Szerokiej gamy tworzywa sztuczne: poliwęglan, PCV, plexi, teflon, poliamidy, gambit, guma, itp.

- Drewno lite oraz płyty drewnopochodne: sklejki, płyty wiórowe, MDF, OSB itp

- Metale miękkie i kolorowe: mosiądz, miedź, brąz, aluminium

- Papier, karton, folia itp.

- Pianki, materiały ekstrudowane, itp.

- Oraz wiele innych materiałów

5 Osiowe Studio CNC Seron oferuje wysoką precyzję, dynamiczną pracę i szybkość. Wykorzystywane w przemyśle motoryzacyjnym, lotniczym oraz przy produkcji modeli, form do termoformowania, laminowania, odlewania, rzeźb i elementów 3D. Dzięki solidnej i ergonomicznej konstrukcji, umożliwia obróbkę dużych gabarytów z powtarzalnością i najwyższą precyzją

3 Osiowe Studio CNC Seron

Maszyny CNC 3-osiowe to zaawansowane narzędzia do obróbki skrawaniem, które umożliwiają precyzyjne ruchy narzędzia w trzech niezależnych osiach: X, Y i Z. Dzięki temu są idealne do wykonywania różnorodnych operacji obróbczych. Maszyny te charakteryzują się solidną konstrukcją, wysoką dokładnością oraz możliwością pracy z różnymi materiałami. Są wyposażone w nowoczesne systemy sterowania, które zapewniają łatwość obsługi i programowania, co pozwala na efektywne i precyzyjne wykonywanie zadań produkcyjnych.

Kluczowe cechy:

Maksymalne wymiary obróbki: 2000 x 3000 x 1000 mm.

- Rozmiar stołu: 2100 x 3100mm

- Zakres w osi Z: 300 mm

- Prędkość wrzeciona: 24,000 obr./min

- Moc silnika wrzeciona: 13,5 kW

- Pojemność magazynu narzędzi: 34 sztuki

- Nośność stołu: 350 kg

- Stół podciśnieniowy i nóż oscylacyjny

- Szerokiej gamy tworzywa sztuczne: poliwęglan, PCV, plexi, teflon, poliamidy, gambit, guma, itp.

- Drewno lite oraz płyty drewnopochodne: sklejki, płyty wiórowe, MDF, OSB itp

- Metale miękkie i kolorowe: mosiądz, miedź, brąz, aluminium

- Papier, karton, folia itp.

- Pianki, materiały ekstrudowane, itp.

- Oraz wiele innych materiałów

Haas TM1-P

Idealne rozwiązanie dla firm z branży motoryzacyjnej, lotniczej i produkcji precyzyjnej, poszukujących wysokiej jakości obróbki na Podkarpaciu i w całej Polsce.

Kluczowe Cechy i Korzyści:

Kompaktowa, ale Wydajna Przestrzeń Robocza:

Przejazdy: X: 760 mm, Y: 400 mm, Z: 400 mm

Nośność stołu: 150 kg Umożliwia precyzyjną obróbkę małych i średnich detali, idealna do produkcji części maszynowych i prototypów.

Wszechstronność Materiałowa

Specjalizujemy się w obróbce:

Aluminium – idealne dla przemysłu lotniczego i automotive

Stal węglowa – do zastosowań przemysłowych i narzędziowych

Możliwość obróbki innych materiałów na życzenie klienta

SD ZEISS T-SCAN Hawk 2

Zaawansowany skaner 3D T-Scan Hawk 2, stworzony przez firmę ZEISS, jest ręcznym urządzeniem o niewielkiej wadze, które charakteryzuje się prostotą obsługi. Jego mobilność sprawia, że znajduje zastosowanie w różnych sektorach i sytuacjach, takich jak monitorowanie jakości, odwzorowywanie konstrukcji, utrzymanie ruchu, czy naprawy.

Kluczowe cechy:

- Dokładność przestrzenna 0.02mm + 0.015mm/m (2)

- Certyfikowane (DAkks / ILAC)

- Inspekcja 3D wgnieceń, korozji i uszkodzeń

- Skanowanie 3D i regeneracja starszych części

- Praca w pomieszczeniach i na zewnątrz w trudnych warunkach przemysłowych

- Monitorowanie zużycia

Inżynieria odwrotna:

- Od modelu rzeczywistego do CAD

- Archiwizacja narzędzi i obiektów dóbr kultury

- Od małych detali po bardzo duże części

Kontroli jakości:

- Porównanie danych aktualnych z CAD

- Funkcjonalne wymiarowanie

- Inspekcja na produkcji

Projektowanie:

- Digitalizacja złożonych kształtów i obiektów fizycznych

- Modyfikacja projektu

- Projektowanie wnętrz

- Wizualizacja 3D

Dzięki swojej zaawansowanej technologii, T-Scan Hawk 2 jest w stanie dostarczyć precyzyjne dane pomiarowe w każdym momencie i każdym miejscu. Skaner działa efektywnie nawet w miejscach o ograniczonym dostępie lub na powierzchniach o różnej teksturze i kolorze, oferując najwyższą jakość danych pomiarowych 3D.

T-Scan Hawk 2 jest niezastąpionym narzędziem w różnych branżach, takich jak motoryzacja, transport morski i kolejowy, lotnictwo, energetyka czy produkcja form i maszyn.

Współrzędnościowa maszyna pomiarowa Aberlink Horizon 800

Idealne rozwiązanie dla firm z branży motoryzacyjnej, lotniczej, produkcji precyzyjnej i kontroli jakości, poszukujących najwyższej dokładności pomiarów na Podkarpaciu i w całej Polsce.

Kluczowe Cechy i Korzyści:

Przestrzeń Robocza i Technologia

- Przejazdy: X: 800 mm, Y: 1600 mm, Z: 600 mm

- Dopuszczalne obciążenie: 1000 kg

- Napędy liniowe dla płynnego ruchu

- Głowica skanująca Renishaw SP25M

Precyzja i zastosowania

- Niepewność pomiaru: (1,75 + L/250)μm

- Idealna do kontroli jakości części wielkogabarytowych

- Umożliwia szybkie i dokładne skanowanie powierzchni

- Kluczowa w produkcji precyzyjnej

Sintratec S3

Laser Sintering Station (LSS) to technologia stosowana w drukarkach 3D, które wykorzystują technikę wybiórczego spiekania laserowego (SLS, Selective Laser Sintering). W tej metodzie, drobny proszek polimerowy (lub metalowy) jest stapiany warstwa po warstwie za pomocą lasera, aby utworzyć trójwymiarowy obiekt.

Kluczowe cechy:

- Średnica plamki lasera: 145μm

- Grubość warstwy: 0,1 mm

- Moc lasera: 30W

- Wysokość komory roboczej: 400mm

- Średnica komory roboczej: 220mm

- Pojemność: 15,2 l

Materiały:

- Nylon PA12

- Nylon z włóknem szklanym PA12 GF

- TPE

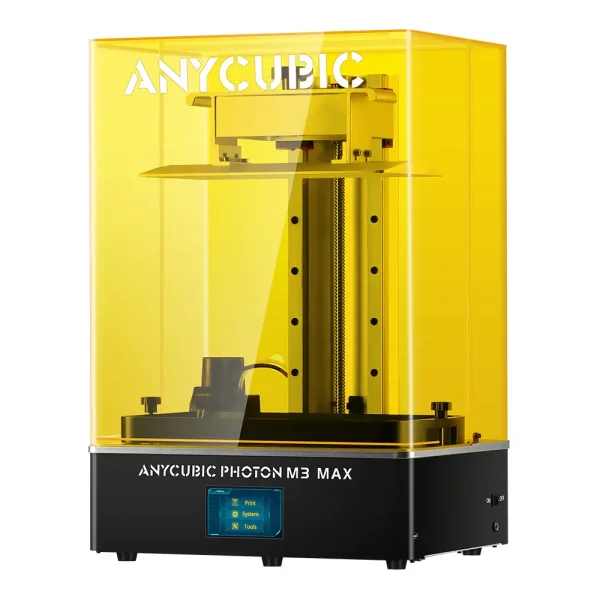

3D Anycubic Photon M3 Max

Technologia SLA (stereolitografia) to metoda druku 3D, która polega na utwardzaniu ciekłej żywicy za pomocą światła UV, kierowanego za pomocą lustrzanych galwanometrów. Obiekt jest tworzony warstwa po warstwie, aż do uzyskania pełnego modelu 3D.

Kluczowe cechy:

- Rozmiar druku: 300 x 298 x 164 mm

- Precyzja druku: 6 480 x 3 600 pikseli (7K

Zalety technologii SLA:

Wysoka dokładność: SLA jest znane z produkcji bardzo dokładnych i szczegółowych modeli, z dokładnością do kilku mikrometrów. Jest to idealne dla precyzyjnych zastosowań, takich jak prototypowanie, stomatologia, biomedycyna itp.

Gładkie powierzchnie: W porównaniu z innymi technologiami druku 3D, takimi jak FDM, modele SLA mają bardzo gładkie powierzchnie, co sprawia, że są idealne do produkcji elementów o wysokim stopniu wykończenia.

Złożone geometrie: SLA pozwala na drukowanie złożonych geometrii, które mogą być trudne lub niemożliwe do wykonania za pomocą innych technologii druku 3D.

Materiały używane w technologii SLA:

Technologia SLA korzysta z żywic fotopolimerowych, które utwardzają się pod wpływem światła UV. Te żywice dostępne są w różnych odmianach, w zależności od wymaganego końcowego zastosowania. Niektóre żywice są zaprojektowane tak, aby były sztywne i odporne na wysokie temperatury, podczas gdy inne mogą być elastyczne lub przeznaczone do zastosowań biomedycznych.

Drukarki FDM

echnologia FDM (Fused Deposition Modeling), znana również jako FFF (Fused Filament Fabrication), jest jedną z najpopularniejszych i najbardziej dostępnych technologii druku 3D. Proces FDM polega na stopniowym wydruku obiektu poprzez nakładanie warstw topionego filamentu plastikowego.

Wydruki 3D oparte na technologii FDM są generalnie tańsze niż te wykorzystujące technologie takie jak SLA czy SLS.

-

PLA (Polikwas mlekowy): PLA ma temperaturę zeszklenia około 60-65°C i wytrzymałość na rozciąganie około 7250 psi.

-

ABS (Akrylonitryl butadien styren): Materiał ten charakteryzuje się dużą sztywnością i trwałością.

-

PET (Politereftalan etylenu): Jest to materiał, który jest twardy, odporny na uderzenia i wilgoć, może być bezpieczny dla żywności.

-

PETG (Glikol politereftalanu etylenu): Jest to wariant PET, który jest mocniejszy i bardziej trwały, wykazuje odporność na ciepło, stres i wilgoć, ale mięknie w temperaturze około 80°C i jest wrażliwy na światło UV.

-

TPU (Termoplastyczny poliuretan): To materiał o właściwościach przypominających gumę, który jest trwały i odporny na ścieranie