Eagle eVision 4kW Laser Cutting Machine

Speed. Accuracy. Technology of the future.

The Eagle eVision 4kW laser cutter is a high-tech sheet metal cutting machine that delivers exceptional precision and impressive performance. With a 4kW laser source and a lightweight axis driven by linear motors, the machine enables cutting at high speeds while maintaining the highest edge quality.

Key features:

- Laser power: 4 kW (fiber)

- Working area: 3000 x 1500 mm

- Positioning speed: up to 150 m/min

- Cutting accuracy even with thin and difficult materials

- Automatic loading and unloading table for increased work efficiency

- Excellent edge quality without the need for additional processing

The Eagle eVision is the solution for those who want speed, reliability and the highest cutting quality – whether producing prototypes or large runs.

Trumpf TruBend 3100 Edge Press

The Trumpf TruBend 3100 press brake is a modern sheet metal bending solution that combines German precision with intuitive operation and high productivity. Ideal for both unit and batch production, it enables repeatable results for even the most demanding bends.

Key features:

- Pressing force: 100 tons

- Bending length: 3000 mm

- High positioning and bending angle accuracy thanks to angle measurement system

- Intuitive Touchpoint TruBend control interface

- Ability to bend complex shapes and thin-walled parts

- Stable and rigid construction for long life

With the TruBend 3100 press, we offer our customers a comprehensive sheet metal bending service with the highest precision, regardless of the shape and size of the part.

CNC Okuma Genos M660

Applications in various industries such as aerospace, automotive, electronics and medical. It is used to produce precision parts, prototypes, injection molds and finished products

Key features:

- Table size: 660x 1530 mm.

- Spindle speed: 15,000 rpm.

- Spindle motor power: 22 kW.

- Tool storage capacity: 32 pieces.

Table load capacity : 1500 kg

- Aluminum

- Stainless steel

- Carbon steel

- Brass

- Copper

- Titan

- Inconel

- And many other materials

This machine features flexibility thanks to its 32-piece tool magazine and excellent cutting performance thanks to its 15K CAT40 BIG-PLUS® spindle. It also stands out for its high rigidity thanks to its double-column design.

The GENOS 560-V-E offers exceptional thermal stability, allowing it to process a wide variety of materials, from titanium to aluminum, without compromising the quality of the finish.

Okuma Genos 560-V-E

Applications in various industries such as aerospace, automotive, electronics and medical. It is used to produce precision parts, prototypes, injection molds and finished products

Key features:

- Table size: 560 x 1300 mm.

- Spindle speed: 15,000 rpm.

- Spindle motor power: 22 kW.

- Tool storage capacity: 32 pieces.

Table load capacity : 900 kg

- Aluminum

- Stainless steel

- Carbon steel

- Brass

- Copper

- Titan

- Inconel

- And many other materials

This machine features flexibility thanks to its 32-piece tool magazine and excellent cutting performance thanks to its 15K CAT40 BIG-PLUS® spindle. It also stands out for its high rigidity thanks to its double-column design.

The GENOS 560-V-E offers exceptional thermal stability, allowing it to process a wide variety of materials, from titanium to aluminum, without compromising the quality of the finish.

Okuma LB 3000 EXII MY

CNC lathes with a Y-axis for milling offer expanded machining capabilities compared to traditional lathes. With a Y-axis that adds vertical motion to the standard X-axis (horizontal motion) and Z-axis (longitudinal motion) movements, CNC lathes with a Y-axis are able to perform precision milling operations, making it possible to create complex shapes and workpieces.

Key features:

- Over-bed clearance: 520 mm

- Maximum turning diameter 340 mm

- Maximum turning length 950 mm

- Maximum spindle load 650 kg

- Spindle motor power: 22 kW

- Spindle speed: 38 ~ 3800 rpm

Rotary tools:

- Tool rotation range: 45 ~ 6000 rpm

- Maximum motor power of driven tools: 5.5 kW

- Clamping force: 6.5 kN

- Aluminum

- Stainless steel

- Carbon steel

- Brass

- Copper

- Titan

- Inconel

- And many other materials

Okuma Genos L3000-e

CNC lathes with a Y-axis for milling offer expanded machining capabilities compared to traditional lathes. With a Y-axis that adds vertical motion to the standard X-axis (horizontal motion) and Z-axis (longitudinal motion) movements, CNC lathes with a Y-axis are able to perform precision milling operations, making it possible to create complex shapes and workpieces.

Key features:

- Over-bed clearance: 520 mm

- Maximum turning diameter 390 mm

- Maximum turning length 950 mm

- Maximum spindle load 650 kg

- Spindle motor power: 22 kW

- Spindle speed: 38 ~ 3800 rpm

Rotary tools:

- Tool rotation range: 45 ~ 6000 rpm

- Maximum motor power of driven tools: 5.5 kW

- Clamping force: 6.5 kN

- Aluminum

- Stainless steel

- Carbon steel

- Brass

- Copper

- Titan

- Inconel

- And many other materials

The Okuma GENOS L3000-e CNC lathe is an advanced machine that uses a built-in spindle for accurate CNC machining. A more powerful lathe, this lathe excels at machining many unusual materials. The built-in spindle drive enhances machining capabilities, while the robust guideways enable intensive cutting. This highly advanced lathe offers a variety of functions, such as high-speed milling and use of the Y-axis .The use of TAS-C thermoactive stabilizer technology, allows it to automatically compensate for temperature effects and maintain tight tolerances.

Okuma Genos 560-V-E

Applications in various industries such as aerospace, automotive, electronics and medical. It is used to produce precision parts, prototypes, injection molds and finished products

Key features:

- Table size: 560 x 1300 mm.

- Spindle speed: 15,000 rpm.

- Spindle motor power: 22 kW.

- Tool storage capacity: 32 pieces.

Table load capacity : 900 kg

- Aluminum

- Stainless steel

- Carbon steel

- Brass

- Copper

- Titan

- Inconel

- And many other materials

This machine features flexibility thanks to its 32-piece tool magazine and excellent cutting performance thanks to its 15K CAT40 BIG-PLUS® spindle. It also stands out for its high rigidity thanks to its double-column design.

The GENOS 560-V-E offers exceptional thermal stability, allowing it to process a wide variety of materials, from titanium to aluminum, without compromising the quality of the finish.

5 Axis Seron CNC Studio

CNC 5-axis machines are advanced machining tools that allow tool movement in five independent axes. In addition to the standard X-, Y- and Z-axis movements, 5-axis CNC machines are capable of rotary movements around the A- and B-axes, providing greater freedom and precision during machining.

With five axes of motion, 5-axis CNC machines allow cutting from different angles and positions, which is especially useful for machining hard-to-reach areas and making complex shapes. These machines allow milling, drilling, threading and other machining operations to be performed with high precision and efficiency

Key features:

Maximum processing dimensions: 2000 x 3000 x 1000 mm.

- Table size: 2100 x 3100mm

- Range in Z axis: 1000 mm

- Spindle speed: 24,000 rpm

- Spindle motor power: 13.5 kW

- Tool storage capacity: 34 pieces

- A wide range of plastics: polycarbonate, PVC, Plexiglas, Teflon, polyamides, gambit, rubber, etc.

- Solid wood and wood-based boards: plywood, particleboard, MDF, OSB, etc.

- Soft and non-ferrous metals: brass, copper, bronze, aluminum

- Paper, cardboard, foil, etc.

- Foams, extruded materials, etc.

- And many other materials

Seron’s 5 Axis CNC Studio offers high precision, dynamic operation and speed. It is used in the automotive and aerospace industries and in the production of models, molds for thermoforming, laminating, casting, sculptures and 3D parts. Thanks to its robust and ergonomic design, it enables processing of large dimensions with repeatability and highest precision

3 Axis Seron CNC Studio

CNC 3-axis machines are advanced machining tools that allow precise tool movements in three independent axes: X, Y and Z. This makes them ideal for performing a variety of machining operations. These machines are characterized by robust construction, high accuracy and the ability to work with a variety of materials. They are equipped with state-of-the-art control systems that ensure ease of operation and programming, allowing for efficient and precise production tasks.

Key features:

Maximum processing dimensions: 2000 x 3000 x 1000 mm.

- Table size: 2100 x 3100mm

- Z-axis range: 300 mm

- Spindle speed: 24,000 rpm

- Spindle motor power: 13.5 kW

- Tool storage capacity: 34 pieces

- Load capacity of the table: 350 kg

- Vacuum table and oscillating knife

- A wide range of plastics: polycarbonate, PVC, Plexiglas, Teflon, polyamides, gambit, rubber, etc.

- Solid wood and wood-based boards: plywood, particleboard, MDF, OSB, etc.

- Soft and non-ferrous metals: brass, copper, bronze, aluminum

- Paper, cardboard, foil, etc.

- Foams, extruded materials, etc.

- And many other materials

Haas TM1-P

Ideal for automotive, aerospace and precision manufacturing companies looking for high quality machining in the Podkarpackie region and throughout Poland.

Key Features and Benefits:

Compact but Efficient Workspace:

Passages: X: 760 mm, Y: 400 mm, Z: 400 mm

Table load capacity: 150 kg Enables precision machining of small and medium-sized parts, ideal for machine parts and prototype production.

Material Versatility

We specialize in machining:

Aluminum – ideal for aerospace and automotive applications

Carbon steel – for industrial and tooling applications

Can machine other materials upon request

SD ZEISS T-SCAN Hawk 2

The advanced 3D scanner T-Scan Hawk 2, developed by ZEISS, is a handheld, lightweight device that features simplicity of operation. Its mobility makes it applicable to a variety of sectors and situations, such as quality monitoring, structural mapping, maintenance, and repair.

Key features:

- Spatial accuracy 0.02mm + 0.015mm/m (2)

- Certified (DAkks / ILAC)

- 3D inspection of dents, corrosion and damage

- 3D scanning and remanufacturing of older parts

- Indoor and outdoor operation in harsh industrial environments

- Monitoring consumption

Reverse engineering:

- From real model to CAD

- Archiving of tools and objects of cultural property

- From small details to very large parts

Quality Control:

- Comparison of current data with CAD

- Functional sizing

- Inspection at production

Design:

- Digitization of complex shapes and physical objects

- Design modification

- Interior design

- 3D visualization

Thanks to its advanced technology, the T-Scan Hawk 2 is capable of providing precise measurement data at any time and anywhere. The scanner works effectively even in restricted areas or on surfaces with different textures and colors, offering the highest quality 3D measurement data.

T-Scan Hawk 2 is an indispensable tool in various industries such as automotive, marine and rail transportation, aviation, energy, or mold and machine manufacturing.

Aberlink Horizon 800 coordinate measuring machine

Ideal for companies in the automotive, aerospace, precision manufacturing and quality control industries looking for the highest accuracy of measurements in the Podkarpackie region and across the country.

Key Features and Benefits:

Workspace and Technology

- Passages: X: 800 mm, Y: 1600 mm, Z: 600 mm

- Permissible load: 1000 kg

- Linear drives for smooth motion

- Renishaw SP25M scanning head

Precision and applications

- Measurement uncertainty: (1.75 + L/250)μm

- Ideal for quality control of large-size parts

- Enables fast and accurate scanning of surfaces

- Key in precision manufacturing

Sintratec S3

Laser Sintering Station (LSS) is a technology used in 3D printers that use selective laser sintering (SLS, Selective Laser Sintering). In this method, a fine polymer (or metal) powder is fused layer by layer using a laser to create a 3D object.

Key features:

- Laser spot diameter: 145μm

- Layer thickness: 0.1 mm

- Laser power: 30W

- Working chamber height: 400mm

- Working chamber diameter: 220mm

- Capacity: 15.2 l

Materials:

- Nylon PA12

- Nylon with glass fiber PA12 GF

- TPE

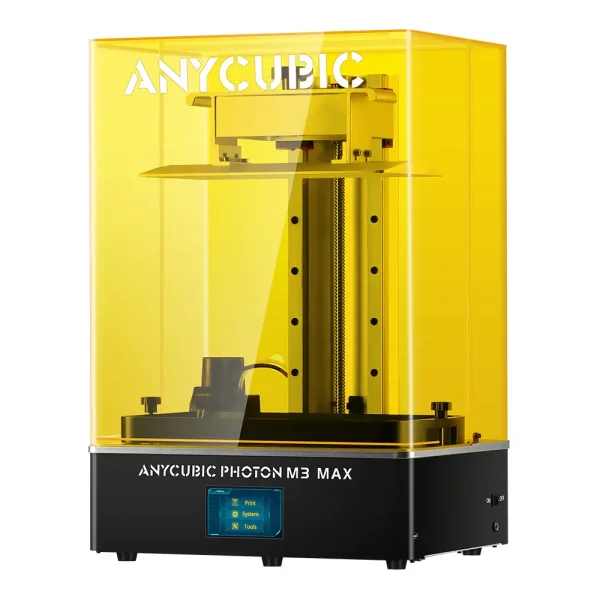

3D Anycubic Photon M3 Max

SLA (stereolithography) technology is a 3D printing method that involves curing liquid resin with UV light, guided by mirrored galvanometers. The object is created layer by layer until a full 3D model is achieved.

Key features:

- Print size: 300 x 298 x 164 mm

- Printing precision: 6,480 x 3,600 pixels (7K

Advantages of SLA technology:

High accuracy: SLA is known for producing highly accurate and detailed models, with accuracy down to a few micrometers. This is ideal for precision applications such as prototyping, dentistry, biomedicine, etc.

Smooth surfaces: Compared to other 3D printing technologies such as FDM, SLA models have very smooth surfaces, making them ideal for producing highly finished parts.

Complex geometries: SLA allows for the printing of complex geometries that may be difficult or impossible with other 3D printing technologies.

Materials used in SLA technology:

SLA technology uses photopolymer resins that cure under UV light. These resins are available in different varieties, depending on the required end use. Some resins are designed to be rigid and resistant to high temperatures, while others may be flexible or designed for biomedical applications.

FDM printers

he FDM (Fused Deposition Modeling) technology, also known as FFF (Fused Filament Fabrication), is one of the most popular and accessible 3D printing technologies. The FDM process involves the gradual printing of an object by applying layers of fused plastic filament.

FDM-based 3D printing is generally less expensive than those using technologies such as SLA or SLS.

-

PLA (Poly-Lactic Acid): PLA has a glass transition temperature of about 60-65°C and a tensile strength of about 7250 psi.

-

ABS (acrylonitrile butadiene styrene): This material is characterized by high rigidity and durability.

-

PET (Polyethylene terephthalate): This is a material that is tough, resistant to impact and moisture, and can be food safe.

-

PETG (Polyethylene Terephthalate Glycol): This is a variant of PET that is stronger and more durable, shows resistance to heat, stress and moisture, but softens at about 80°C and is sensitive to UV light.

-

TPU (Thermoplastic Polyurethane): This is a material with rubber-like properties that is durable and abrasion-resistant