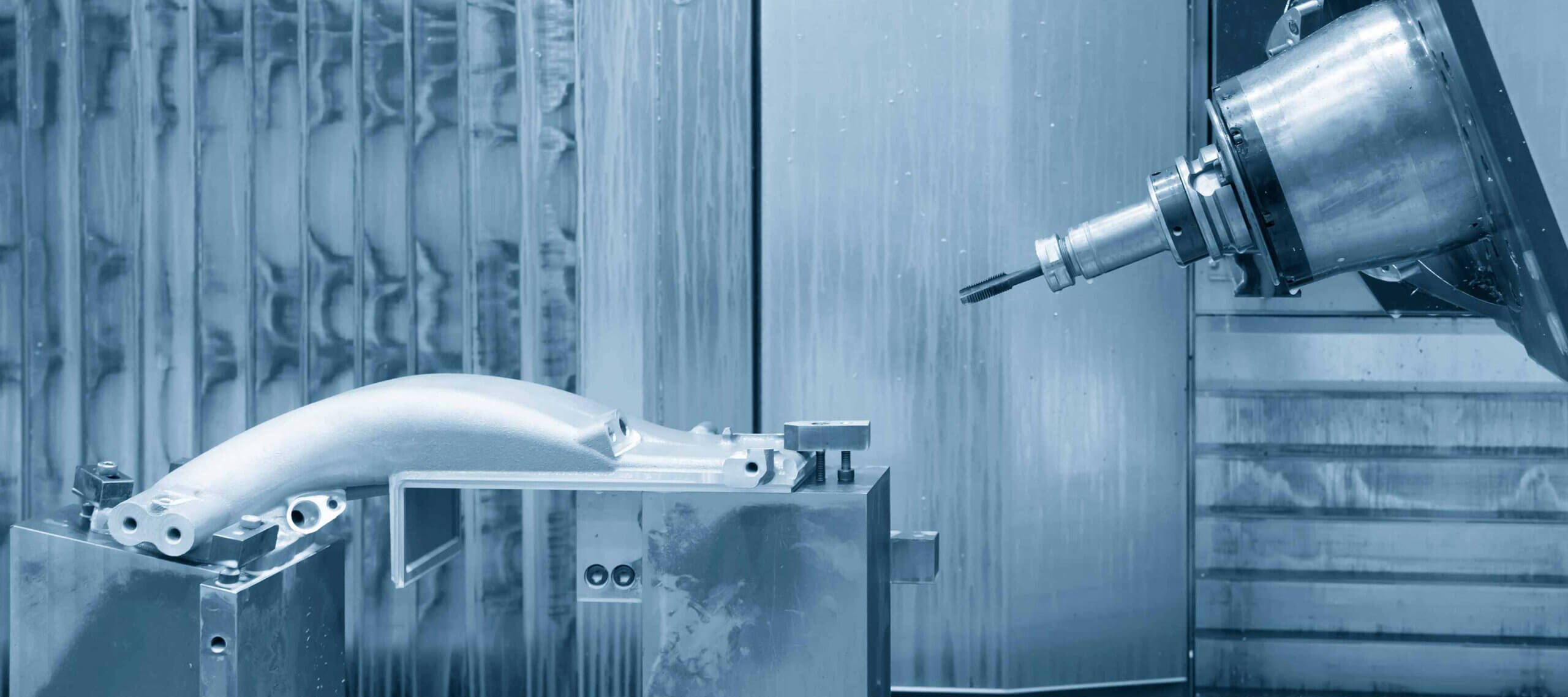

CNC Milling – Precision and Scalability in Large-Size Machining

Our Podkarpackie-based company specializes in providing advanced CNC services, including large-scale, five-axis milling. Thanks to our state-of-the-art machines and technology, we can carry out projects requiring precise machining of large components and complex shapes, both in Poland and throughout Europe.

We offer large-scale CNC milling, which can process components with impressive dimensions of up to 1x2x3 meters. Equipped with advanced control systems and precision spindles, our CNC machines are specifically designed to work with large components. Using the latest technology, we can handle complex projects that require precise milling of large, heterogeneous parts.

Benefits of Large Volume Milling

- Efficiency and Speed – A large work area allows larger workpieces to be processed in a single work cycle, reducing production time and increasing efficiency.

- Precision Machining – With a large working area and the ability to machine large components simultaneously, we ensure high dimensional accuracy and excellent surface finish.

- Reduce Costs – Machining large parts in a single work cycle leads to a reduction in machine preparation costs and reduces consumption of consumables.

- Versatility – The ability to machine a variety of materials and shapes, from structural components to precision parts, enabling a wide range of projects in the industry.

Applications of Large-Size Milling

- Structural Component Manufacturing – Our CNC machines are ideal for creating large components used in the building and construction industry.

- Building and Construction – Machining of large structural components such as wall panels, beams and prefabricated elements.

- Machinery Industry – Precision milling of large machine parts, housing components and frames.

- Furniture and Furnishings – Milling of large furniture components, such as countertops and cabinet fronts.

- Five-axis CNC Milling – Technology and Benefits

Five-Axis CNC Milling Technology

Five-axis CNC milling is an advanced technology that enables the precise machining of complex shapes in multiple planes. With five axes of rotation and translation, our CNC machines allow the machining of parts with complex geometries and irregular shapes.

Benefits of Five-Axis CNC Milling

- Multidirectional Mach ining – The ability to machine in multiple planes simultaneously increases precision and efficiency.

- Reduced Downtime – Reduces the need for multiple fixturing and alignment of parts, which speeds up production.

- Precision Detailing – Enables processing of complex and irregular shapes with high accuracy.

- Quality Enhancement – Guarantees excellent surface finish and dimensional accuracy.

Applications of Five-Axis CNC Milling.

- Prototyping and Unit Production – Ideal for prototyping and one-off parts with complex shapes.

- Aerospace and Automotive – Precision engine components, structural parts and tools.

- Medical Manufacturing – Implants and Surgical Instruments.

- Advertising and Exhibition Mockups – Creating complex advertising and exhibition mockups.

- Furniture and Furnishings – Manufacturing furniture and furnishings components with complex geometries.

High Performance Spindle – Key to Efficiency

Spindle Specifications

Our CNC machines are equipped with a powerful spindle that reaches speeds of up to 24,000 revolutions per minute and 11 kW of power. Such a spindle ensures faster machining and precise finishing of parts.

Benefits of High-Performance Spindle

Faster Machining – The high speed of the spindle allows material to be processed faster, increasing production efficiency.

- Precision Finish – With high power and speed, the spindle provides excellent surface finish and dimensional accuracy.

- Increased Efficiency – Optimize the milling process, resulting in less downtime and lower production costs.

Materials and Applications

Material Machining Capabilities

Our CNC milling services cover a wide range of materials, including:

- Metals of Color – Aluminum, copper, brass, which are often used in the engineering and construction industries.

- Plastics– Including various types of plastics that are used in prototyping and manufacturing machine parts.

- Composite Materials – Such as carbon and glass fibers, which are used in the aerospace and automotive industries.

- Foams – Soft materials, such as polyurethane foams, used in a variety of applications, from prototypes to finishing components.

- Wood – Including solid wood and particleboard, which are used in the production of furniture and decorative elements.

Applications

- Prototyping and Unit Production – Ideal for prototyping and producing parts with complex geometries.

- Advertising and Exhibition Mockups– Milling of complex advertising and exhibition mockups and models.

- Furniture and Furnishings – Manufacturing large and precise furniture and furnishings items.

- Aerospace and Automotive – Machining of precision components for the aerospace and automotive industries.

With advanced CNC milling services and five-axis milling technology, we are able to meet the most demanding projects. Our experience and advanced technologies guarantee the highest quality and precision in material processing, making us the ideal partner for a wide variety of manufacturing projects.